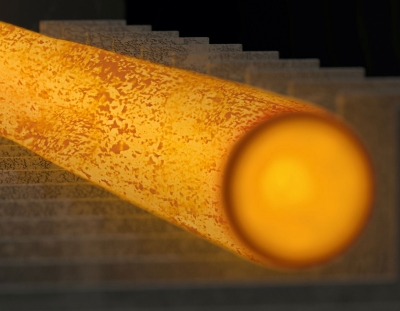

Pyrometers have proven their worth for measuring the temperature during piercing, stretching and finish rolling. They measure the infrared radiation of the objects and calculate the temperature according to the Planck’s law of radiation. The radiation is measured contactless from a safe distance and without destroying the workpiece. The temperature is recorded in a few milliseconds and serves as a monitoring and control variable for the heating and rolling process.

To avoid the interference of scale and oxide, the pyrometers have a CSD (Clean Surface Detection) function. In combination with a high-resolution lens and a very short measuring time, the true temperatures are filtered out of the scale- and oxide-free surface.

Pyrometers in steel processing

Application reports on temperature measurement of steel

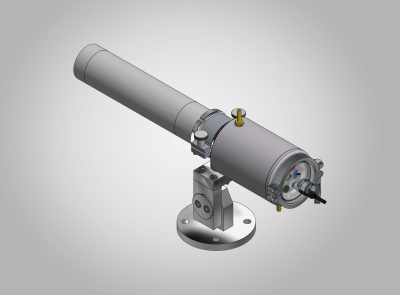

Application report tube rolling mill

Features

- CSD (Clean Surface Detection) function to detect true object temperature

- very high optical resolution for measuring hot spots from a safe distance

- two-colour (ratio) measuring method for reliable measurement despite dust, vapour and smoke

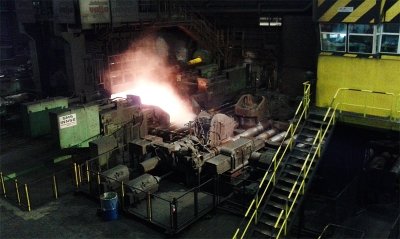

Application report rolling stand

To determine the slab temperature, optical pyrometers are used, which measure the infrared radiation of the object without contact from a safe distance and determine the temperature from this. At the relevant measuring points, there is a risk of heavy water vapour and smoke in the pyrometer's field of view. However, in order to measure the temperature reliably, two-colour pyrometers are used.

The two-colour measuring method compensates for such interferences and indicates the correct temperature even if the infrared radiation is weakened by intermediate media.

The two-colour measuring method compensates for such interferences and indicates the correct temperature even if the infrared radiation is weakened by intermediate media.

Features

- short-wave two-colour measuring method for object temperatures from 500 °C

- choice of sighting devices: through-the-lens sighting, laser pilot light or video camera

- compact design or as fibre optic version with separate optical measuring head

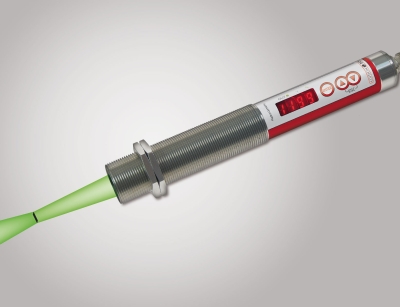

Application report metal strips

Measuring metal strips at low temperatures is a challenging measurement task for non-contact temperature measurement due to the very low thermal radiation and the special radiation properties of metals. For object temperatures from approx. 75 °C, short-wave measuring devices can be used. However, these devices react sensitively to interference from artificial light or sunlight up to approx. 150 °C object temperature. For reliable measurement at low temperatures, measures to shade out the external radiation of daylight are therefore necessary.

Features

- system solutions for low temperature measurement of metal strips

- wear-free and maintenance-free pyrometers based on constant light technology

- patented measuring method for the detection of the smallest infrared radiation

Application report CellaWire

Temperature-controlled rolling is the prerequisite for achieving the desired material properties while at the same time maximizing efficiency in wire production. In order to be able to ensure today's high demands on the required close tolerances of the rolling temperature, modern measuring methods and measuring systems suitable for the respective measuring points are required.

Pyrometers have proved their worth for measuring the temperature of the wire rod blocks and the wire. The radiation is measured optically and contactless from a safe distance and thus without destroying the workpiece.

To avoid the interference of scale and oxide, the pyrometers have a CSD (Clean Surface Detection) function. In combination with a high-resolution lens and a very short measuring time, the true temperatures are filtered out of the scale- and oxide-free surface.

Pyrometers have proved their worth for measuring the temperature of the wire rod blocks and the wire. The radiation is measured optically and contactless from a safe distance and thus without destroying the workpiece.

To avoid the interference of scale and oxide, the pyrometers have a CSD (Clean Surface Detection) function. In combination with a high-resolution lens and a very short measuring time, the true temperatures are filtered out of the scale- and oxide-free surface.

Features

- CSD (Clean Surface Detection) function to detect true object temperature

- very high optical resolution for measuring even small bars from a safe distance

- choice of sighting devices: through-the-lens sighting, laser pilot light or video camera

Application report metal strips

Measuring metal strips at low temperatures is a challenging measurement task for non-contact temperature measurement due to the very low thermal radiation and the special radiation properties of metals. For object temperatures from approx. 75 °C, short-wave measuring devices can be used. However, these devices react sensitively to interference from artificial light or sunlight up to approx. 150 °C object temperature. For reliable measurement at low temperatures, measures to shade out the external radiation of daylight are therefore necessary.

Features

- system solutions for low temperature measurement of metal strips

- wear-free and maintenance-free pyrometers based on constant light technology

- patented measuring method for the detection of the smallest infrared radiation