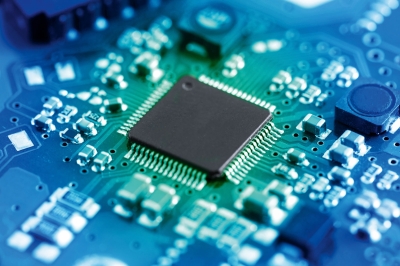

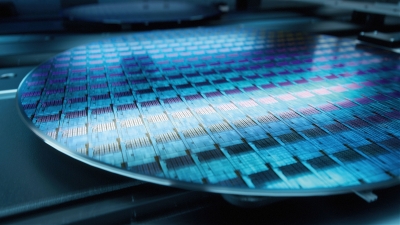

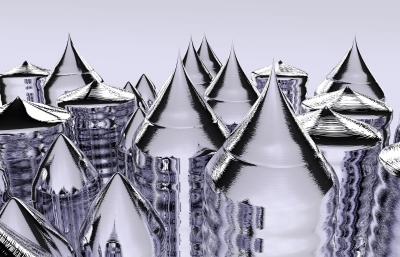

The semiconductor industry is a rapidly growing market with increasing demands on the performance and production costs of its products, such as photovoltaic cells, microchips, LEDs and lasers. The process chains for producing these products include the extraction of a pure semiconductor substrate with a crystal lattice that is as flawless as possible and its further processing. This further processing includes the thermal treatment and coating of wafers.

The process temperature is a decisive factor in the semiconductor production. In crystal growth and wafer processing, specific temperature ranges must be observed in order to avoid defects and thus achieve a high yield. Real-time temperature measurement is thus of crucial importance. Optical temperature measurement with pyrometers is the ideal method to quickly determine the exact process temperature from the infrared radiation of the semiconductors without contact. The demanding and multiple measurement tasks require optimally customized pyrometer solutions.

Pyrometers in the semiconductor industry

Application report on optical temperature measurement in crystal growth and wafer processing

Application report semiconductor industry

Features

- Very large measuring spans thanks to hybrid signal processing with consistently high signal resolution over the entire measuring range

- Broadband anti-reflective precision lenses for high optical resolution

- Special calibration at the process temperature

- Extremely high long-term stability thanks to drift-free sensor technology based on constant light technology