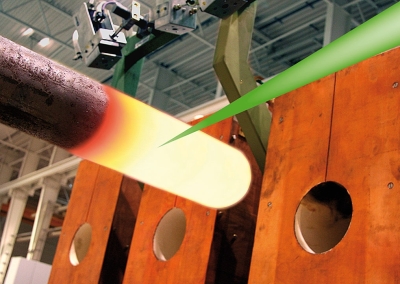

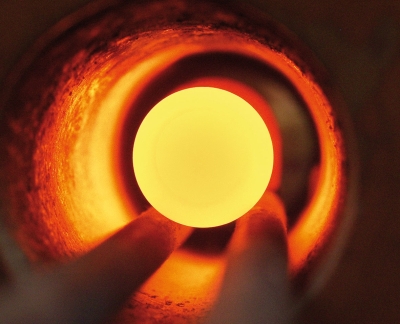

Induction heating systems are the typical preliminary stage for automatic forming processes. Before forging, pressing or rolling, the billets, blocks, bars or ingots are heated to the required temperature. In order to be able to ensure an even distribution of heat, it is necessary to precisely record and maintain the optimum forging temperature.

To achieve high material throughput and short cycle times at the same time, pyrometers are ideally suited for fast, reliable and non-destructive measurement of the temperature at the outlet of the heating furnace before the forming process.

Pyrometers for induction heating plants

Application report on temperature measurement of bolts, blocks, billets and rods in forming processes

Application report CellaInduction

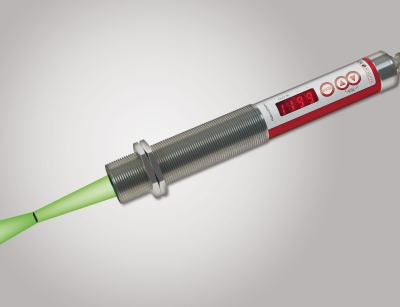

Features

- extensive portfolio of single-colour and two-colour pyrometers

- patented LED pilot light for imaging the exact measuring field

- choice of round or rectangular measuring field