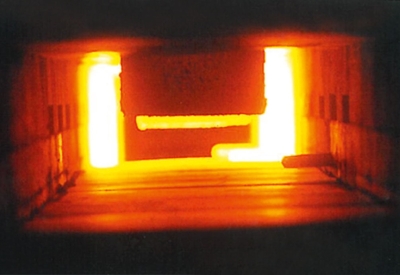

In the manufacture of ceramic products, the temperature curve in the furnace has a significant influence on the reject rate and fuel consumption. For optimal furnace control, accurate measuring devices are therefore required, which ideally record the material temperature directly.

Pyrometers have proved their worth for measuring the temperature. They measure the infrared radiation of the objects and calculate the temperature from it. The measurement is carried out optically and thus wear-free from a safe distance. The measurement takes place in a few milliseconds. Pyrometers can therefore be used to maintain the optimum firing curve much more precisely and thus minimize fuel consumption.

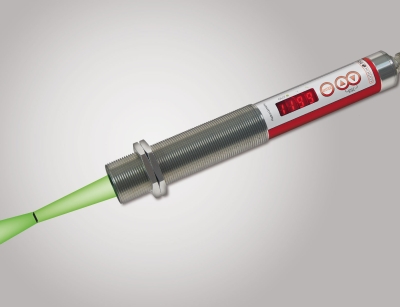

Pyrometers for furnaces

Application report on non-contact temperature measurement in furnaces

Application report on furnace applications

Features

- application solutions for all relevant measuring points

- compact design with integrated temperature display

- short measuring time and thus precise control of the furnace temperature