The quality and yield of the coke as well as the service life of the coke oven depend on the temperature and temperature equilibrium of the coke oven chambers in the coke oven battery. In order to be able to meet the high metrological requirements of the harsh measuring conditions and very high ambient temperatures, modern measuring methods and measuring systems developed for the respective measuring points are absolutely essential. Temperature-controlled production is the prerequisite for achieving the desired material properties with maximum efficiency.

At the relevant measuring points, the pyrometer's field of view is affected by water vapor and heavy dust and smoke formation. If the temperature is to be reliably recorded here, ratio pyrometers are absolutely essential. A ratio pyrometer compensates for these influences and still displays the correct temperature even if the infrared radiation is attenuated.

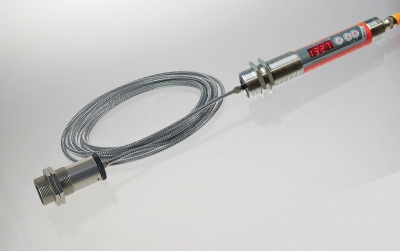

Pyrometers with a separate optical measuring head are used due to the high ambient temperature at the measuring location. An optical fiber transmits the infrared radiation to the electronics mounted in a safe area.

Pyrometers in the coking plant

Application report on optical temperature measurement in the coke battery

Coking plant application report

Features

- Reliable temperature measurement based on the quotient measuring method

- Small optical measuring head M16 for mounting inside the pusher arm

- Fiber optic pyrometer with separate optics and electronics with fiber optic lengths of up to 50 m