Company history

The history of the KELLER company

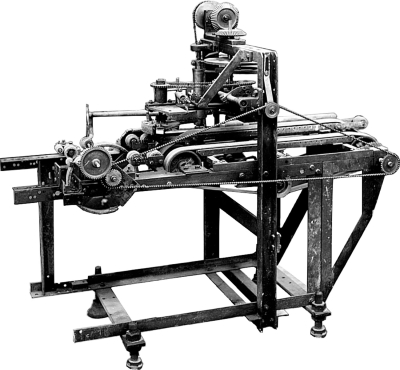

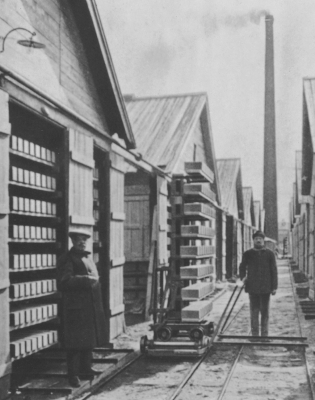

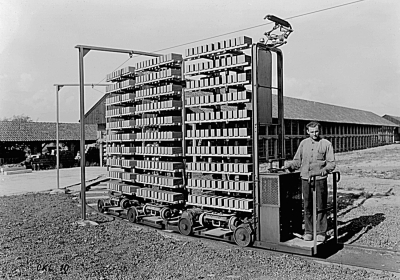

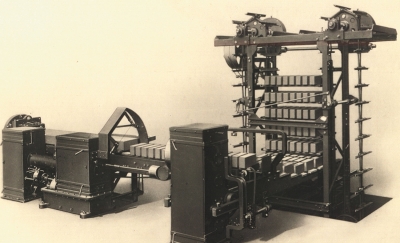

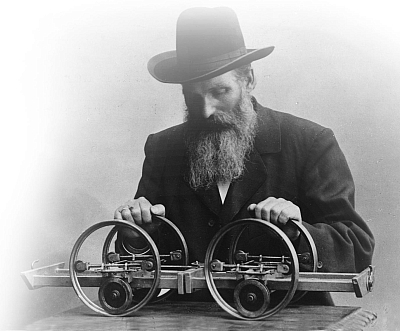

In 1894, the Laggenbeck machinist Carl Keller (1847-1932) invented the finger car. This rather inconspicuous-looking device marked the beginning of automation in the brick industry. Keller's realisation that his finger car had no chance without a functioning dryer system was the drive for further groundbreaking developments.

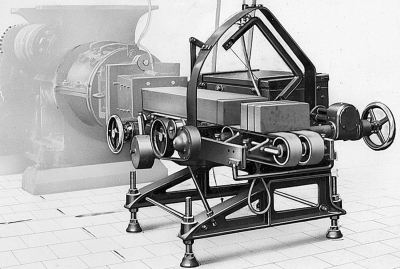

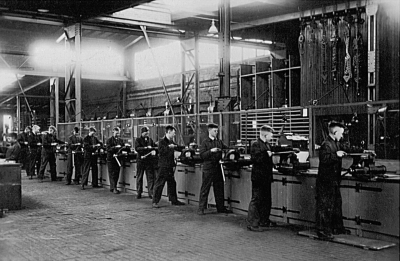

Carl Keller initially found an Osnabrück company as a partner, which patented his finger car and received permission from him to build and market it for 10 years. However, he was not satisfied with the quality of the finger cars built and set up his own repair shop in Laggenbeck, where he reworked them. After the patent expired, he took over production at the Laggenbeck site in 1904. A few years later, the product range had already been expanded to include turning and lifting devices, transfer cars and elevators. In 1910, the first fully automatic brick handling machine of the "Hörstel" type, a combination of cutter, pallet conveyor and elevator, was developed. This was the breakthrough to mechanisation.

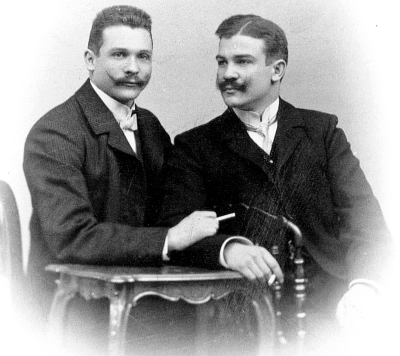

Carl Keller put a lot of heart and soul into marketing and selling his products. Even before World War I, he travelled to Russia, where the first fully automatic machine was subsequently installed in Astrakhan on the Caspian Sea.

Carl Keller put a lot of heart and soul into marketing and selling his products. Even before World War I, he travelled to Russia, where the first fully automatic machine was subsequently installed in Astrakhan on the Caspian Sea.

Carl Keller (1847 - 1932)

As part of the reparations to be paid by the German Reich after World War I, KELLER supplied machines to northern France and Belgium. The first machines were also sold to Uruguay and Argentina.

As part of the reparations to be paid by the German Reich after World War I , KELLER supplied machines to northern France and Belgium. First machines were also sold to Uruguay and Argentina.

After the difficult years of the world economic crisis at the beginning of the 1930s, business picked up again from then on. KELLER regained its old domestic and foreign markets and also found increased access to the underdeveloped southeastern European countries.

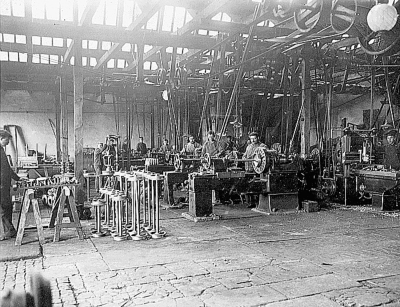

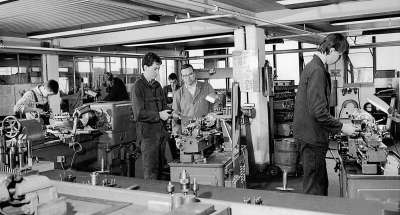

During World War II , KELLER became an arms factory. Russian prisoners of war were assigned to the company, and most of the company's own core workers had been drafted into the military. A quarter of them were killed in the war.

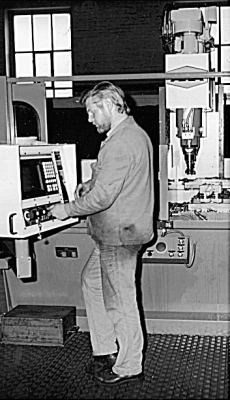

The sister company KELLER Spezialtechnik, founded in 1954, which developed and manufactured control and measurement systems for dryers, took over the majority of the Pyro-Werk Hanover in 1967, which had been producing pyrometers for non-contact temperature measurement since 1925. In 1971, the administration and production were moved from Hanover to Laggenbeck. In 1977, KELLER Spezialtechnik and Pyro-Werk merged to form KELLER Spezialtechnik-Pyrowerk GmbH. In 1990, this company became the MSR business unit.

In addition to the systematic development and the worldwide sale of pyrometers, the MSR business unit also established its own automation department. The core of this department is the control of plants in the bulk solids industry such as grain mills and compound feed plants.

KELLER is an economical, innovative and globally acting company. In addition to continuous technological development, the trusting partnership with our customers and their satisfaction is our top priority.

KELLER has been a division of the French Groupe Legris Industries since 2006.

In 2018, the business areas were reorganized.

As part of the reparations to be paid by the German Reich after World War I , KELLER supplied machines to northern France and Belgium. First machines were also sold to Uruguay and Argentina.

After the difficult years of the world economic crisis at the beginning of the 1930s, business picked up again from then on. KELLER regained its old domestic and foreign markets and also found increased access to the underdeveloped southeastern European countries.

During World War II , KELLER became an arms factory. Russian prisoners of war were assigned to the company, and most of the company's own core workers had been drafted into the military. A quarter of them were killed in the war.

The sister company KELLER Spezialtechnik, founded in 1954, which developed and manufactured control and measurement systems for dryers, took over the majority of the Pyro-Werk Hanover in 1967, which had been producing pyrometers for non-contact temperature measurement since 1925. In 1971, the administration and production were moved from Hanover to Laggenbeck. In 1977, KELLER Spezialtechnik and Pyro-Werk merged to form KELLER Spezialtechnik-Pyrowerk GmbH. In 1990, this company became the MSR business unit.

In addition to the systematic development and the worldwide sale of pyrometers, the MSR business unit also established its own automation department. The core of this department is the control of plants in the bulk solids industry such as grain mills and compound feed plants.

KELLER is an economical, innovative and globally acting company. In addition to continuous technological development, the trusting partnership with our customers and their satisfaction is our top priority.

KELLER has been a division of the French Groupe Legris Industries since 2006.

In 2018, the business areas were reorganized.