Our various dryer types, such as tunnel and chamber dryers, ensure energy-saving and gentle drying of your products. Thanks to our K-Matic process control system, we always guarantee reliable control of the drying process, an optimum overview, repeatability and extensive process evaluation options.

If very individual drying times and drying curves are required, these can be ideally realized with the KELLER chamber dryers. With consistent drying conditions, KELLER tunnel dryers offer the best conditions for energy-efficient drying with high throughputs and first-class product quality.

Drying process

Dryer technology

Ventilation systems

KELLER dryers are available with different ventilation systems. Depending on the product, product geometry, drying temperature and drying time, we select the optimum system for your application.

The following extensive portfolio of systems is available:

The following extensive portfolio of systems is available:

- rotary fan

- stationary jet wall

- movable jet wall

- meander

- single horizontal

- double horizontal

- Paraflow

Heating

The need for heating with renewable energy sources has risen sharply in the course of the energy transition.

We offer you a wide range of options for heating your dryers using both fossil fuels and sustainable fuels such as:

We offer you a wide range of options for heating your dryers using both fossil fuels and sustainable fuels such as:

- gas burner plants with fan burners and surface burners

- diesel burners

- low calorific gas burners such as wood gas burners or coal gas burners

- microturbines with exhaust gas utilization

- electric heating registers, electric duct heaters and electric hot gas generators

Heat recovery

Energy recovery is crucial to increasing energy efficiency. This involves extracting energy from exhaust gas flows and feeding it back into the process.

This happens, for example, with:

This happens, for example, with:

- a recovery of wet air energy at the dryer

- coupled with the use of heat pumps

- the use of heat exchangers in the flue gas made of metal and polymer

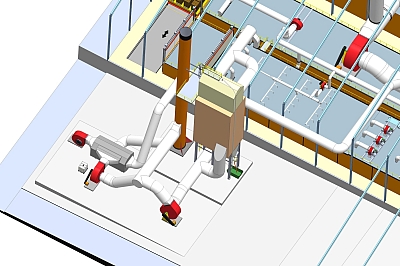

Engineering

Energy consumption during drying and firing is directly related to heat transfer and flow conditions.

CFD calculations help to find thermodynamically and fluid-dynamically optimized solutions in advance. This is why we use them.

CFD calculations help to find thermodynamically and fluid-dynamically optimized solutions in advance. This is why we use them.