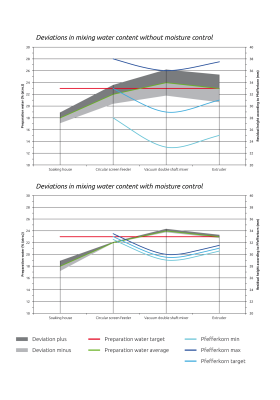

An uniform moisture of the factory blend is essential for an efficient and reproducible production of ceramic products. Therefore, a precisely adjusted preparation water content represents an important factor in terms of shaping technology.

With the K-Matic Moisture Control, KELLER - in cooperation with the company Nordson Measurement and Control (formerly NDC Technologies) - offers the operator a simple possibility to permanently monitor and directly react to changes in the preparation water content through continuous measurement and display of the measured value.

Moisture measurement

K-Matic Moisture Control

K-Matic Moisture Control - reliable measurements directly in the production

Moisture control, such as on the circular screen feeder, can reduce the deviation of the preparation water content from the setpoint and thus have a decisive influence on the product quality.

Main advantages:

- reduction of rejects

- competitive advantage through continuous high product quality

- faster product launches and product changeovers

- Continuous measured value of material moisture - no waiting for the result of a moisture analysis, which moreover only reflects the condition of the material at the time of sampling.

- Clear measured values enable even inexperienced operating personnel to react adequately to variations in the preparation water content.

- Automation of the required water addition is possible, as the measured value can be transmitted and evaluated both analogue (4 - 20 mA) and digital (e.g. Profibus, Ethernet) via various interfaces.

- avoidance of plant damages due to overload caused by excessively stiff material

Measurement principle

- The radiation of a certain wavelength from the infrared range is absorbed by the water contained in the product.

- The radiation of different wavelengths reflected by the product is directed to a detector.

- A processor compares intensities.

- Special algorithms generate an output value from detected infrared signals.

- Sensor must be adjusted to the respective material by calibration measurements.

Frequent applications:

- aggregates such as sawdust, paper making sludge, sand

- biomass

- ceramic materials

If your application is not explicitly mentioned, as well as for questions and further information, please feel free to email us at service@keller.de.