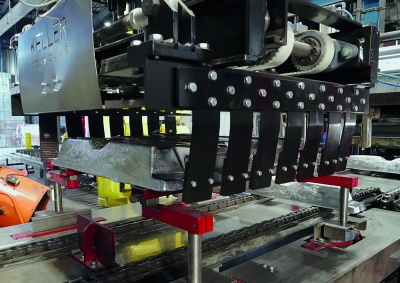

The KELLER handling technology is continuously being developed and we are constantly facing up to the challenges of the market.

Our conventional and robot-assisted handling systems are specially designed for handling unit loads in abrasive environments.

In the building materials as well as in related industries, our technology is characterized by a long service life and low wear and tear under heavy stress.

Handling systems

Innovative handling technology by KELLER

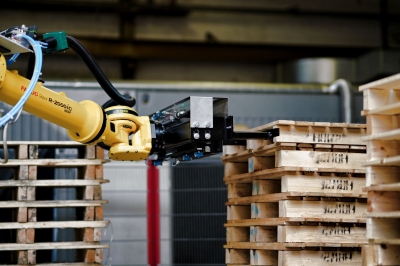

Robot systems - the perfect handling solution

Robot solutions from KELLER are held in high esteem in other areas also beyond the heavy clay industry. The following overview provides an insight into the variety of applications in which KELLER robotic systems provide trouble-free and reliable service on a daily basis:

KELLER robot systems in related industries:

- concrete

- wood cement

- aerated concrete

- sand-lime bricks

- refractories

KELLER robot systems in other industries:

- paints (e.g. paint buckets)

- foundry (e.g. ingots)

- glass (e.g. glass tubes)

- pallets

- automotive (e.g. spark plugs)

- animal feed

- food (e.g. confectionery, frozen food)

- paper and packaging (e.g. paperboard)

Special features of the KELLER robot systems:

- optimal integration into any production process

- high reliability even when working around the clock

- gentle handling of products

- maximum flexibility when changing products

- easy programming

- worldwide remote diagnosis and remote maintenance