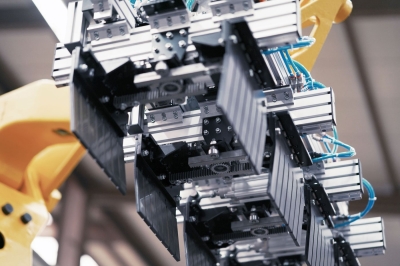

Simple gripping tasks can be performed with standardized grippers. However, for the automated gripping of complex components and for non-standard automation tasks, special grippers with special designs are often required.

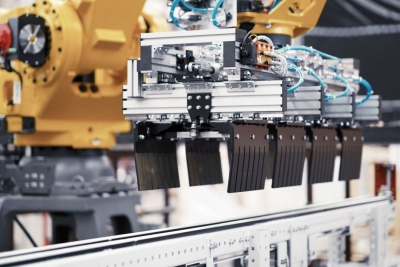

KELLER's innovative gripper solutions which are proven around the world perform a wide variety of automation and handling tasks. Whether industrial or gantry robots, the innovative tools and grippers from KELLER increase your automation, flexibility, accelerate processes and reduce your operating costs.

The variety and sometimes the uniqueness of the products to be handled require special tools and solutions. We offer you the optimal solution for your application, always keeping an eye on the total costs.

Our grippers are not only limited to “opening” and “closing”, they also “turn, group and create gaps between” the products during the handling and robot cycle, thus replacing some of the additional equipment and machinery that would otherwise be needed.

Gripper technology

Cutting-edge gripper technology made by KELLER

Everything needed for handling tasks - gripper technology made by KELLER

With a feeling for what is feasible, Keller’s highly qualified engineers plan, develop, design and assemble not only the most complex gripping systems. Complete solutions and deliveries including industrial or portal robots and their assembly and commissioning as well as the respective safety equipment are part of Keller’s core competence. For example, the working ranges of industrial robots can be extended by our linear axes, which are adapted to your application.

Based on many years of experience, we provide support with:

- feasibility studies and simulations

- the adaptation of new grippers in your plant

- programming and commissioning

- supply of complete solutions, including e.g. inlet and outlet transport and grouping devices