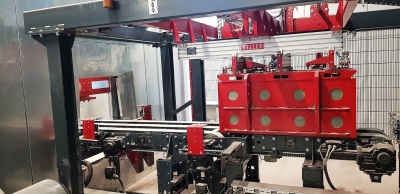

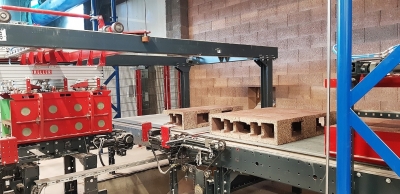

The scope of supply includes the complete processing of the previously pressed wood-concrete blocks.

The system consists of two milling stations for face milling, groove milling and chamfer milling. It is able to process the wood-concrete blocks with a maximum capacity of 1450 blocks per hour. The bricks are then grouped and palletized.

For this project, KELLER used its proven transport and robot technology to develop its product portfolio into a suitable special solution.

Wood concrete

You can find BU IMS industry solutions here

Plant for finishing and packing of wood concrete blocks