Burner technology

Implementation of energy optimization measures

The focus is always on energy savings in connection with the reduction of combustion air volumes or at least the use of preheated combustion air.

Our offer includes:

- Full service - starting with documentation of burner plants and their adjustment

- Use know-how - for the design of burner performance according to the firing curve

- Selection of the right burner technology - using the example of KELLER burners CF10, CF20, LVB, HVB, HT

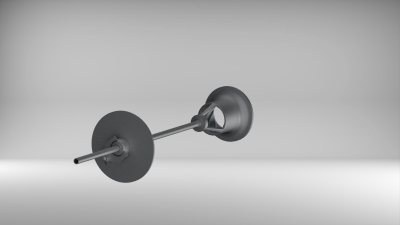

Pure gas burner without primary air type HT - support for CO2 reduction and increased energy efficiency

The supply of external combustion air can be completely omitted when using pure gas burners.

In relation to the individual burner, around 30 % energy can be saved.

In relation to the individual burner, around 30 % energy can be saved.

Technical data

- The throw distance of the pure gas burner is approx. 2 m.

- Due to the Venturi effect of the pure gas burner, the circulation rate is 350 m³/h.

- The pure gas burner can be used for a variety of fuel types such as natural gas, propane gas, hydrogen and mixed gases.

- The pure gas burner is suitable for a temperature range greater than or equal to 750 °C.