The existing Keller setting machine was replaced by a new machine concept.

Starting with the pallet unloading equipment, the new setting plant places common bricks and ceiling bricks on kiln cars for firing. Depending on the cutting length, packs of 4 or 5 rows are formed.

The former pack unloading system was replaced by a new system for the unloading of bricks in layers; here the proven KELLER concept could be successfully implemented. In front of the packaging plant, a KELLER grinding machine can be installed at a later date.

The required plant capacity could be exceeded.

Common bricks

References of the ICS business unit can be found here

LEIER, Turcin - New fully automatic setting, unloading and packaging plant in Croatia

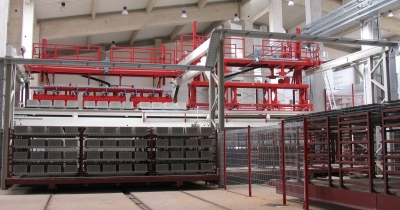

El-Khayyat, Al-Khumra - KELLER supplies three of the world's largest brick plants to Saudi Arabia

In 2014, the largest order in KELLER's history was signed.

In 2018, plants I and II were accepted and handed over to the customer, as well as plant III in 2019. Three of the largest brick plants in the world were thus put into operation.

Each plant produces 1700 t of fired common bricks per day. This could be used to build up to 40 detached houses!

A comparison shows the enormous capacity of the plants: an average German brick plant produces around 300 to 400 t of fired goods per day.

In 2018, plants I and II were accepted and handed over to the customer, as well as plant III in 2019. Three of the largest brick plants in the world were thus put into operation.

Each plant produces 1700 t of fired common bricks per day. This could be used to build up to 40 detached houses!

A comparison shows the enormous capacity of the plants: an average German brick plant produces around 300 to 400 t of fired goods per day.

HELUZ, Hevlin - Common bricks from the Czech Republic

A completely new production plant for the manufacture of highly porous backing bricks with a capacity of 800 t per day of fired goods was built on the existing plant site. The plant can produce different formats with a brick density of up to 0.6 kg/dm³. Grinding of the entire production is possible.

A completely new production plant for the manufacture of highly porous common bricks with a capacity of 800 t per day of fired goods was built on the existing plant site. Different sizes with a brick bulk density of up to 0.6 kg/dm³ can be produced in the plant. Grinding of the entire production is possible.

Clay from the existing pit is used as the basic raw material for the production of common bricks, to which sawdust and papermaking sludge are added as pore-forming materials.

It is also possible to use polystyrene as an additive.

The necessary material tests were carried out in the KELLER application laboratory.

Clay from the existing pit is used as the basic raw material for the production of common bricks, to which sawdust and papermaking sludge are added as pore-forming materials.

It is also possible to use polystyrene as an additive.

The necessary material tests were carried out in the KELLER application laboratory.