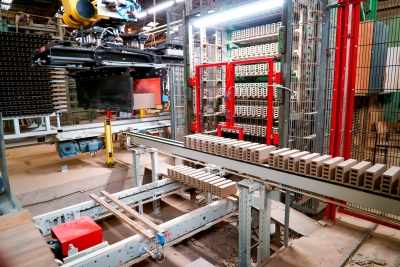

Despite regular maintenance, the old automatic separating and feeding system had fallen into a state in which the number of faults and the associated downtimes were increasing to such an extent that modernisation was absolutely necessary.

The task for the new plant was to get the maximum out of the possibilities. This is not necessarily due to performance, but more to the variety of tasks required.

This was fulfilled with a robot and an adapted gripping tool. A sophisticated sensor system, which is used to detect or exclude the sources of faults and possibilities, serves to safeguard operation.

Since its commissioning, the robot has been operating at an output of approx. 65%. More is hardly necessary to fulfill the desired output. The whole package ensures that potential accidents in the plant have been greatly reduced.

Ceramic plates

References of the ICS business unit can be found here

Ammonit Keramik, Ostercappeln - Small robot plant with many tasks

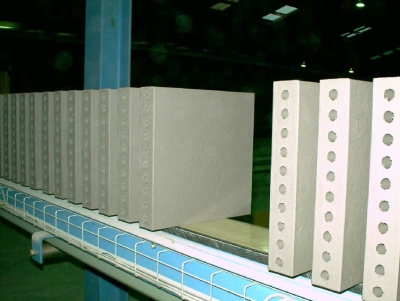

AUSTRAL, Punchbowl - Split tile plant implemented with Ecorapid technology

The plant will produce 900,000 m² of split tiles per year. The realized plant concept is not only suitable for the production of split tiles and split tile accessories, but also for the manufacture of other products. The small number of machines with the variable drying system as well as the side-fired kiln allow a high size variety and make this type of plant so flexible.