The KELLER wall panel technology is continuously being developed and we are constantly facing up to the challenges of the market.

The KELLER production systems for prefabricated wall panels offer you the possibility to produce effectively and economically.

The integration of energy efficiency, ecological housing features or heat, fire and sound insulation is taken into account.

Wall panel systems

Innovative KELLER wall panel technology

Benefits of prefabricated wall panels:

- consistently high workmanship quality

- cost-effective shell construction

- short construction time

- fixed budget

- adherence to schedules in the construction process

- easier work, especially for the site crew

- prefabrication independent of weather conditions

- product finishing or further processing

Production plants for prefabricated wall panels - highest manufacturing precision

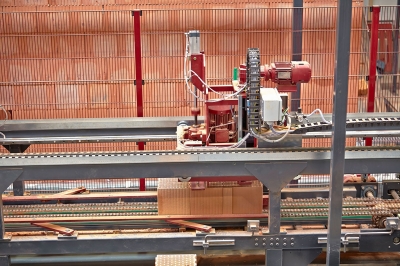

The fully automatic KELLER production systems for prefabricated wall panels are mainly used by brick manufacturers and large manufacturing companies. Bricks, sand-lime bricks, aerated concrete and other bricks are used.

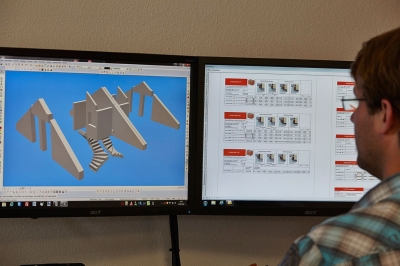

The core of the system is the K-matic-WALL wall panel program, which handles the entire logistics including data exchange with the classic PLC. Here, the architects' CAD data is converted into information that can be read by the PLC for production. The calculation of the required number of bricks, the precise ordering of the bricks, their arrangement in the wall structure, the incorporation of openings and shafts and the positioning of the finished wall elements, etc. are all determined by the developed software. - All of this is determined by the developed software and specified to the individual workstations.

The core of the system is the K-matic-WALL wall panel program, which handles the entire logistics including data exchange with the classic PLC. Here, the architects' CAD data is converted into information that can be read by the PLC for production. The calculation of the required number of bricks, the precise ordering of the bricks, their arrangement in the wall structure, the incorporation of openings and shafts and the positioning of the finished wall elements, etc. are all determined by the developed software. - All of this is determined by the developed software and specified to the individual workstations.

Production steps:

- preparation of technical data

- preparation for the production

- brick arrangement

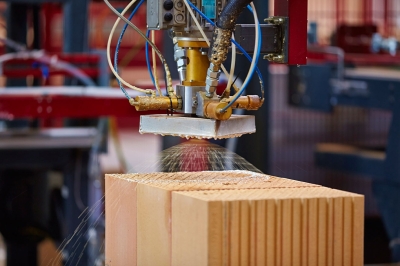

- brick bonding

- individually manufactured wall elements

- finishing