The KELLER handling technology is continuously being developed and we are constantly facing up to the challenges of the market.

Our conventional and robot-assisted handling systems are specially designed for handling unit loads in abrasive environments.

In the building materials as well as in related industries, our technology is characterised by a long service life and low wear and tear under heavy stress.

Handling systems

Innovative handling technology by KELLER

Robot systems in the heavy clay industry

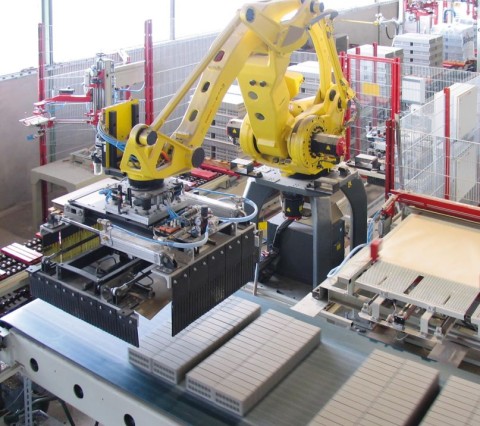

In clay brick plants are used robust palletising robots with payloads of up to 1300 kg. Delta robots are also used for sorting and packing smaller products. They have a total of 4 degrees of freedom with a four-axis wrist.

Today, most of the size changes in brick factories can be achieved fully automatically by using servomotor-driven grippers. Otherwise, gripper stations enable automated gripper changes to be carried out as quickly as they are simple in the event of size or product changes.

In contrast to many other areas of application, the robots used in the heavy clay industry not only have to prove themselves in continuous operation around the clock, they are also exposed to extreme dust and dirt.

Today, most of the size changes in brick factories can be achieved fully automatically by using servomotor-driven grippers. Otherwise, gripper stations enable automated gripper changes to be carried out as quickly as they are simple in the event of size or product changes.

In contrast to many other areas of application, the robots used in the heavy clay industry not only have to prove themselves in continuous operation around the clock, they are also exposed to extreme dust and dirt.

Robot application - wet side

Due to the high preparation water content and their hole pattern, freshly extruded and cut common bricks are always exposed to the risk of being deformed during the further handling process. The handling of the green products on the wet side is therefore regarded as particularly challenging and difficult.

Special features:

- very sensitive design of robot and gripper

- smooth gripping and setting down during the motion sequence

Robot application - Roof Tile Presses

Due to their preparation water content and their shape and size, roof tiles are also exposed to the risk of being deformed during loading and unloading of the roof tile press. Robots and grippers for loading and unloading roof tile presses must therefore also be particularly designed for a careful handling of the products.

Special features

- Very sensitive design of robot and gripper

- Smooth gripping and setting down

Robot application - Setting and Unloading Plants

Robot setting and unloading plants are today's standard in the heavy clay industry. They unload the dryer cars, load and unload the kiln cars and, at the transfer points of the separate areas, they transfer the bricks from one transport line to the other.

Special features

- Flexible design for quick product size changes

- Smooth gripping and precise positioning

- Smooth integration into already existing plants

Robot application - Filling common bricks with insulating materials

With the introduction of the German Energy Saving Ordinance (EnEV) in 2009, filled common bricks have become the new standard in Germany. KELLER played a major part in the development of the filling technology and is considered one of the world's leading manufacturers of filling systems for various insulation materials.

Special features

- Precise cutting and feeding of insulating inserts to be taken up by the filling robot

- Precise and non-compressible introduction of insulating inserts into the bricks in the filling station

Robot application - Packaging and Shipment

In most cases, the packing and shipping robots stack the finished facing bricks, common bricks and pavers directly on pallets, which are then covered with a film hood or strapped and are ready for the transport to the customer. In the case of finished roof tiles, roof tile accessories, floor tiles and facing strips, the finished products are first grouped into packages by 6-axis articulated-arm robots, which are then either shrink-wrapped, banded or packed in outer cartons. 4 axis delta robots are also used for sorting and packing smaller products such as facing strips.

Special features

- Combined gripper and suction devices to grip pallets, intermediate paper layers and bricks

- Suction of the intermediate paper layer and gripping of bricks in one working step

- Servo motor grippers for uninterrupted product size changes for facing and common bricks