Laboratory tests

Benefit from our know-how

The properties and quality of the raw materials have a decisive influence on the production and performance of a plant. In order to be able to provide its customers with optimum support right from the start, KELLER has therefore relied on the company's own application laboratory since 1959. The qualified employees accompany the entire process from the consultation, through the preparation of the quotation to the subsequent plant acceptance.

Knowledge of methods, experience, laboratory equipment and our network of experts form our foundation for precise findings in the field of:

- Ceramic raw materials

- Structural ceramics

- Building materials

- Aggregates

- Additives

We accompany you as required in every phase of your project development, from test drilling in the clay pit to process analysis and optimization in the producing plant.

If your analyse is not explicitly mentioned, as well as for questions and further information, please feel free to email us at keramiklabor@keller.de.

If your analyse is not explicitly mentioned, as well as for questions and further information, please feel free to email us at keramiklabor@keller.de.

Sample collection - new / known occurrences

Our offer includes:

- planning of pit explorations

- monitoring of test drillings

- collection of the raw material samples

- carrying out the necessary laboratory work

- preparation of a extraction plan for the pit area

Preparation of factory blends

Our offer includes:

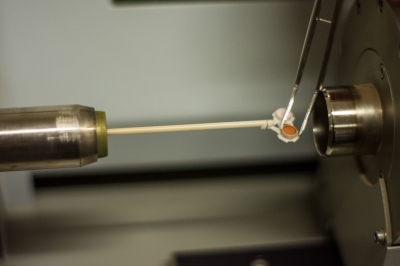

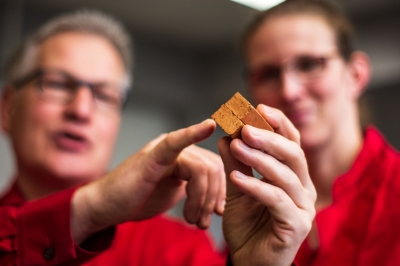

- production of manual test bodies or extrusion of the individual raw materials to determine the material-specific data

- development of a mixture with the required properties

- factory blend development for new products

- development of a factory blend with raw materials from newly explored deposits

- optimization of mixture recipes for improved product characteristics (water absorption, compressive strength, etc.)

- modification of the factory blend with the aim of achieving a more efficient production blend with the same or better product properties

Tests performed:

- shaping qualities

- drying qualities

- firing qualities

- water absorption

- strengths (dry, fired)

- grain size analysis (wet sieving, laser granulometry)

- differential thermal analysis

- dilatometer.

- moisture conductivity

- Bigot measurement

- soluble salts

- full chemical analysis

- mineral phase analysis

Measurements in plants

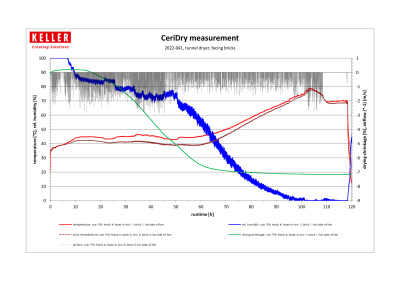

Measurement of quality and environmental data in brick factories

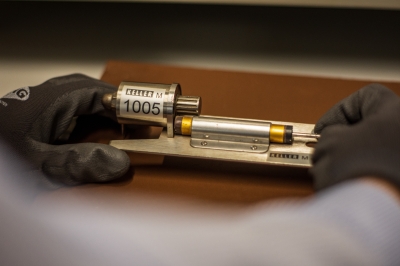

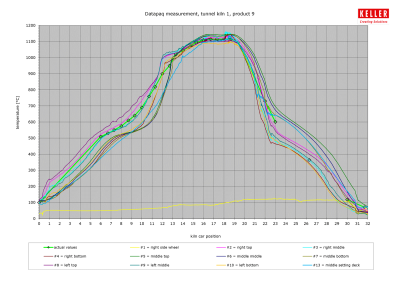

- CeriDry - measurement of relative air humidity, temperature and drying shrinkage in the dryer setting load. Datapaq - measurement of the temperature distribution in the kiln during firing.

Pollutant measurements and measurements of energy and material flows:

- measurements of pollutants (fluorine, chlorine, sulphur, etc.) in air and exhaust gas lines of the plant

- measurements of energy and material flows in the plant

Staff training and coaching

Thanks to our regular worldwide assignments, we have constantly proven expertise and many years of experience in material tests.

Our offer includes:

- training of your staff in methodology and practical application of laboratory tests

- supportive coaching

- joint development of routines for quality testing and control in the ongoing process